/ Our Work / Juxtum Case Study

Infusing Data Analyticsinto IIoT Machine Monitoring

The Challenge | Building a Subscription Model for Data Management

Juxtum is a leading machine monitoring solutions provider, counting major aerospace, defense, automotive, medical, and energy manufacturers as customers. The company’s patented Juxtum Connector technology offers a highly configurable Industrial Internet of Things (IIoT) solution that allows manufacturers to digitize and network their manufacturing assets. Manufacturers can collect data from any manufacturing asset – no matter age, brand, or function – to make smarter operating decisions.

Juxtum recognized that collecting data was only the beginning. The next challenge would be processing and presenting that data for customers to use it effectively. Juxtum set out to create a solution that would allow customers to slice and dice the data, extracting insights to empower business leaders in making informed strategic decisions.

However, Juxtum recognized that collecting data was only the beginning. The next challenge would be processing and presenting that data for customers to use it effectively. Juxtum set out to create a solution that would allow customers to slice and dice the data, extracting insights to empower business leaders in making informed strategic decisions.

In addition, Juxtum wanted to transition its IIoT machine monitoring business to an ongoing subscription revenue model that would enhance its one-time product-sale business.

Results

“We collaborated with CoStrategix to enable machine shops to see their data in ways previously out of reach so they can embrace the future of digital manufacturing and Industry 4.0. This is a game-changer for our customers.”

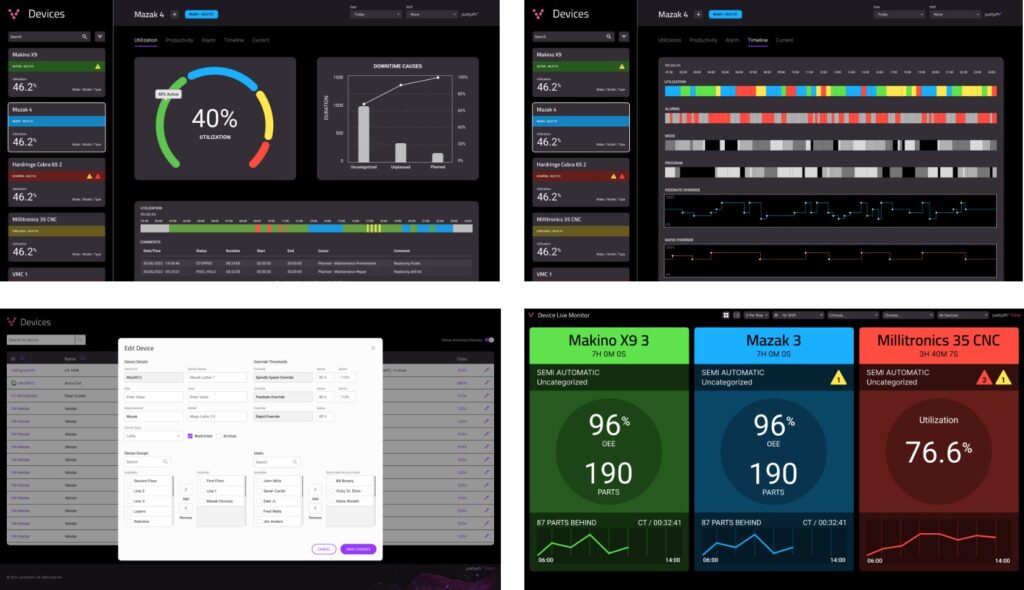

Juxtum engaged CoStrategix to co-create Juxtum View – a tightly coupled system of engagement (SoE) that empowers manufacturers with real-time visualizations and alerts to make insight-driven decisions. Manufacturers can visualize data such as cycle times, part counts, and machine utilization from CNCs, PLCs, sensor devices, and other machines.

With Juxtum View, machine shops can use real-time data to prevent defects, optimize uptime, and improve efficiency – ultimately leading to reduced costs and enhanced productivity. One aerospace customer uses Juxtum View to gain a unified picture of its assets across multiple international locations and help manage and balance its global operations.

Juxtum itself saw a 50 percent increase in its machine monitoring revenue in the last year alone. “Our mission is to simplify the path to IIoT adoption for manufacturers of all sizes,” said Rob Longfellow, Juxtum CTO. “We collaborated with CoStrategix to enable machine shops to see their data in ways previously out of reach so they can embrace the future of digital manufacturing and Industry 4.0. This is a game-changer for our customers.”

The Process

Some of the key challenges included:

- Configuring a distributed deployment model for cloud computing: Juxtum needed to offer manufacturers the option to host their data in the cloud or on-prem. The on-prem option supports locations where security limits internet connectivity.

- Increasing the rate of data availability so customers can see data in real-time: Juxtum View now delivers high-speed throughput, processing thousands of data points per second. With volume that high, the company relies on the latest technology and

serverless cloud computing to continue to scale. - Focusing on experience design to promote usage: The modern look and feel of the Juxtum View interface makes interpreting data from maintenance schedules or operational risks intuitive. It also makes the solution accessible to all users.

“CoStrategix brings a true ‘product mindset,’ constantly focused on continuous improvement,” Longfellow said.

For instance, Juxtum and CoStrategix are jointly developing data science models to implement predictive analytics, such as forecasting machine maintenance needs before issues arise. “We deeply value CoStrategix’s deep experience in data science and AI.”

Juxtum View™ Application

“It seems like every strategic conversation we have with CoStrategix is about what we could be doing. They challenge me to look into the future, instead of focusing on what we’re doing right now.”

Rob Longfellow

Chief Technology Officer